Explosive Environment International Standards & Public Safety for EX & IS Products

Modernized industrial production, processing, transport and storage can create various explosive matters, liquid and gas in the surrounding environment. These products can pose public safety issues. Many Explosion incidents in industrial facilities in recent years highlight the lack of understanding of regulations with regards to these dangerous matters.

Industries that are explosion-prone include but not limited to: Steel, petrochemical, automation, shipping, food production, pharmaceutical, storage automation, recyclable battery, paper pulp, electronics and semiconductor sectors. This resulted in the creation of explosion-proof and intrinsically safe products for siren, flasher, light, strobe and control box.

Explosive Environment Definition

To create an continuous chemical reaction (e.g. explosion), 3 main factors are involved:

- Ignition source

- Oxygen

- Material

From the above, the most commonly ignored aspects are ignition source and material, as most people commonly assume fire as the only ignition source and oil & diesel as the only dangerous materials.

Ignition source should be correctly defined as any source with high energy density. Flame, hot gas, hot temperature surface, machining process, electric current, electric arc, electromagnetic wave, light source, plasma ion, supersonic wave, heat reaction, heat radiation, shockwave and adiabatic compression can be considered as dangerous ignition sources which sets off a kinetic chemical reaction that ultimately ends in explosion.

There are also common misconception in most people that ranks danger in order of: oil and gas > chemicals > everyday goods (ex. Bagasse, corn starch). In reality, everyday goods such as corn starch and bagasse can also create explosive power beyond ones’ imagination. The material risks depend highly on the ignition source, the oxygen’s relative concentration (gas, liquid), the reaction surface area and the energy transition of the material itself. When above conditions are met at the right place and right time, a chain of chemical reaction can occur and set off explosion in a time frame of nanoseconds. Once the positive chain reaction occurs, the reverse process would only stop when either one of the ignition source, oxygen or material is exhausted.

Basics of Explosion Protection Certification Approval

Controlling the ignition source is commonly referred to as intrinsic safety (IS) design. From circuit design, it allows all the electronic components to sustain high potential energy clustering, even under the worse conditions. The electronic circuit would limit the equivalent capacity or limit maximum voltage, current, power or surface temperature. All these standards originate from IEC 60079-11, and varies between different continental standard & regulations such as ATEX, FM, UL, CSA, NEPSI, etc.

Another method of control is to assume that an explosion will occur and thus isolate the product inside to contain the explosion. There would be no flame path resulting in flame propagation. This way, any structural components suffering from corrosion, reliability issues, weathering (such as O-ring degradation) would be explosion-proof and complies with IEC-60079-1, 60079-2 & IEC 60079-13 requirements.

The third method to control ignition source is to isolate it with inert substances, avoiding the possibility of contact with the oxygenated environment. Such oxygen-deficient environment would naturally not cause an explosion. Examples include: inert oil body with high ignition point, inert powder, circuit board coating and electronic equipment injection hardening.

Equipment and Suitable Area Use

Below are the list of Equipment Protection Level (EPL) for different standards:

|

Equipment Protection Level |

ATEX (European standard) |

FM, UL (American standard) |

Risk |

Description |

|

Ga (air, liquid) |

Zone 0 |

Class I |

Very High |

Equipment can be directly placed in an area that is commonly in contact with explosive materials |

|

Gb (air, liquid) |

Zone 1 |

Class I |

High |

Equipment can be indirectly placed in an area that is commonly in contact with explosive materials |

|

Gc (air, liquid) |

Zone 2 |

Class I |

Low |

Equipment can be directly placed in an area that is infrequently in contact with explosive materials |

|

Da (dust) |

Zone 20 |

Class II |

Very High |

Equipment can be directly placed in an area that is commonly in contact with explosive materials |

|

Db (dust) |

Zone 21 |

Class II |

High |

Equipment can be indirectly placed in an area that is commonly in contact with explosive materials |

|

Dc (dust) |

Zone 22 |

Class II |

Low |

Equipment can be directly placed in an area that is infrequently in contact with explosive materials |

|

Ma (underground minerals) |

Energized |

Class III |

|

Underground equipment used in mines are considered as directly in contact with explosive materials. For ignition source that can create energy, it is considered as Energized. |

|

Mb (underground minerals) |

De-Energized |

Class III |

|

Underground equipment used in mines are considered as directly in contact with explosive materials. For ignition source that does not create energy, it is considered as De-Energized. |

Material Explosion Capability Classification

|

Material Explosion Capability |

EU Standard ATEX |

US Standard FM, UL |

Description |

|

Gas, liquid |

I |

Mining |

Representative material - Methane |

|

Gas, liquid |

IIA |

Class I / Group D |

Representative material - Propane |

|

Gas, liquid |

IIB |

Class I / Group C |

Representative material - Ethylene |

|

Gas, liquid |

IIB+H2 |

Class I / Group B |

Representative material - Hydrogen |

|

Gas, liquid |

IIC |

Class I / Group A |

Representative material - Acetylene |

|

Solid, dust |

IIIA |

Class III |

Combustible Flyings |

|

Solid, dust |

IIIB |

Class II, Group G |

Non-Conductive Dust |

|

Solid, dust |

IIIB |

Class II, Group F |

Carbonaceous Dust |

|

Solid, dust |

IIIC |

Class II, Group E |

Conductive Dust |

Temperature Classification

|

Temperature Class |

Atex European Standard |

FM, UL (American Standard NEC 505) |

FM, UL (American Standard NEC 500) |

|

T1 |

450 ℃ |

450 ℃ |

450 ℃ |

|

T2 |

300 ℃ |

300 ℃ |

300 ℃ |

|

T2A |

N/A |

N/A |

280 ℃ |

|

T2B |

N/A |

N/A |

260 ℃ |

|

T2C |

N/A |

N/A |

230 ℃ |

|

T2D |

N/A |

N/A |

215 ℃ |

|

T3 |

200 ℃ |

200 ℃ |

200 ℃ |

|

T3A |

N/A |

N/A |

|

|

T3B |

N/A |

N/A |

|

|

T3C |

N/A |

N/A |

|

|

T4 |

135 ℃ |

135 ℃ |

135 ℃ |

|

T4A |

N/A |

N/A |

120 ℃ |

|

T5 |

100 ℃ |

100 ℃ |

100 ℃ |

|

T6 |

85 ℃ |

85 ℃ |

85 ℃ |

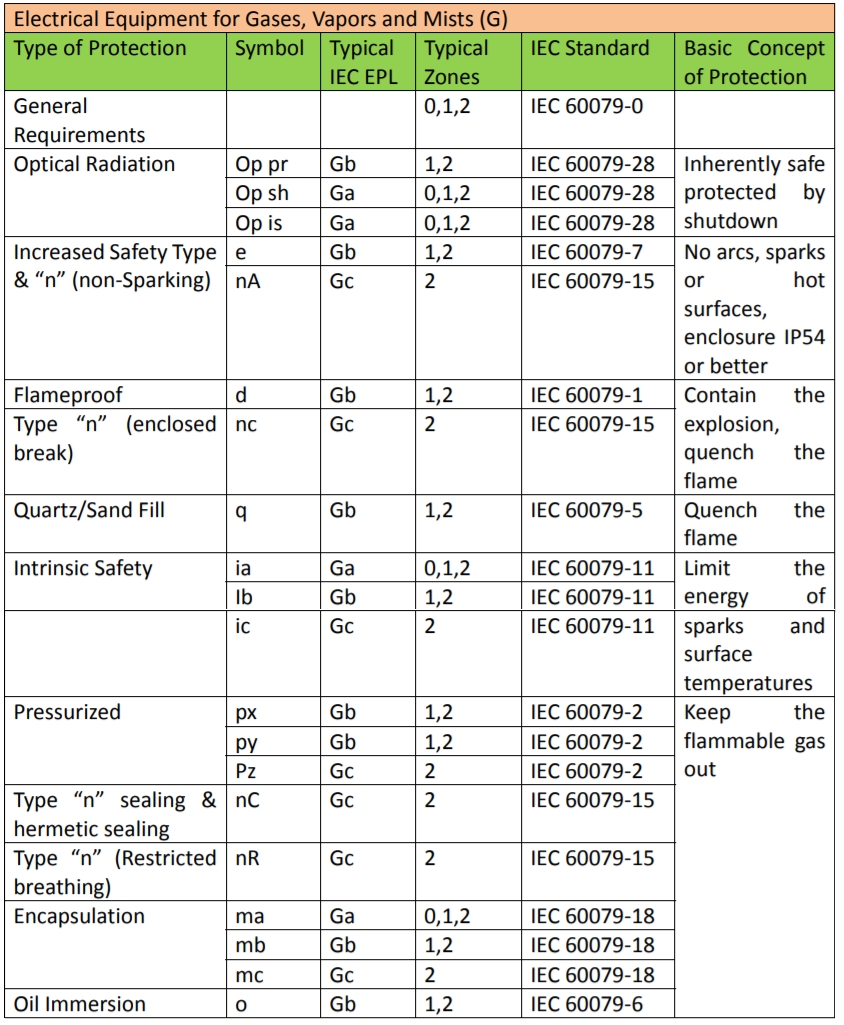

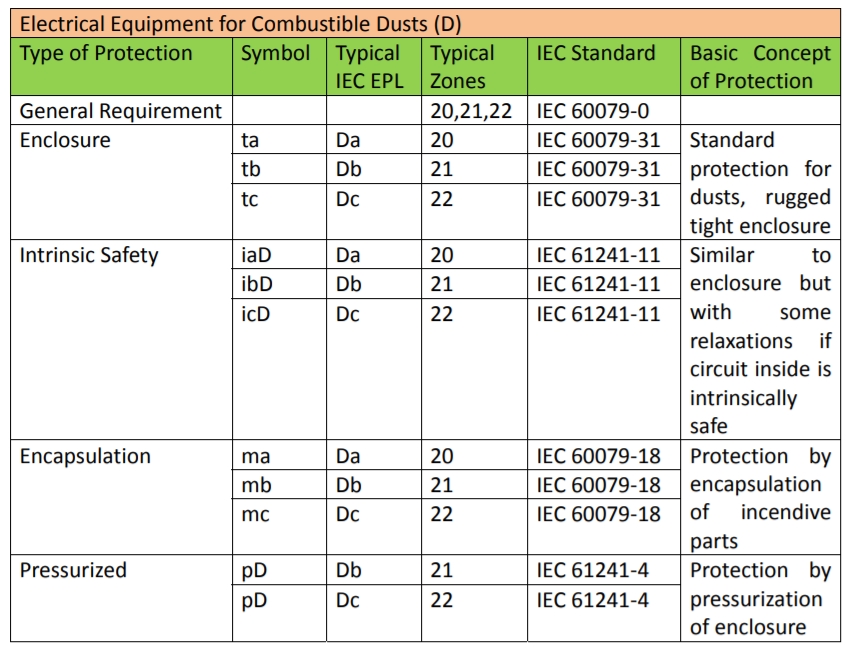

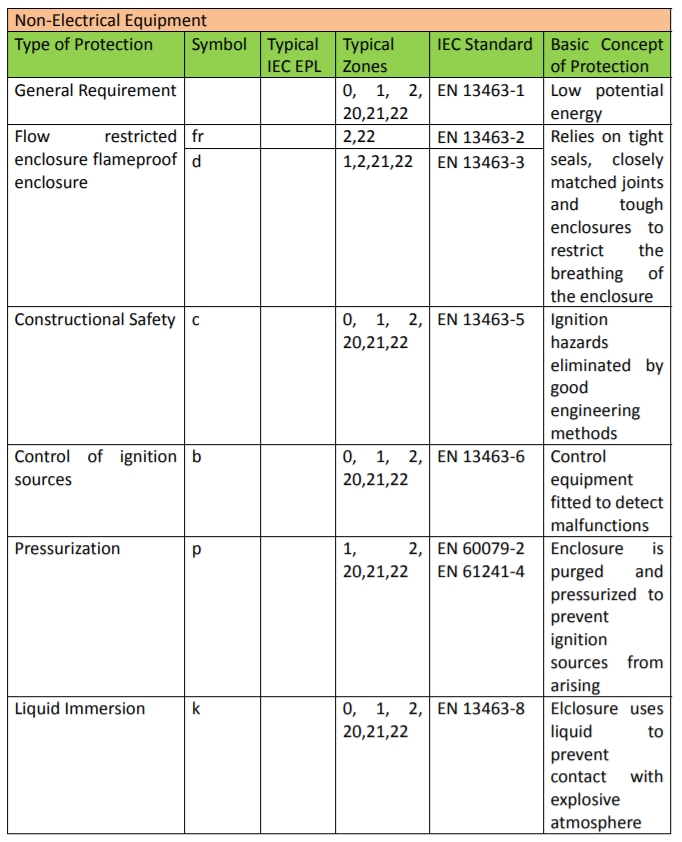

Explosion Protection Types

For any inquiries on intrinsically safe & explosion proof siren, detector, strobe, control box, light & related products, please contact one of our specialists for more information.